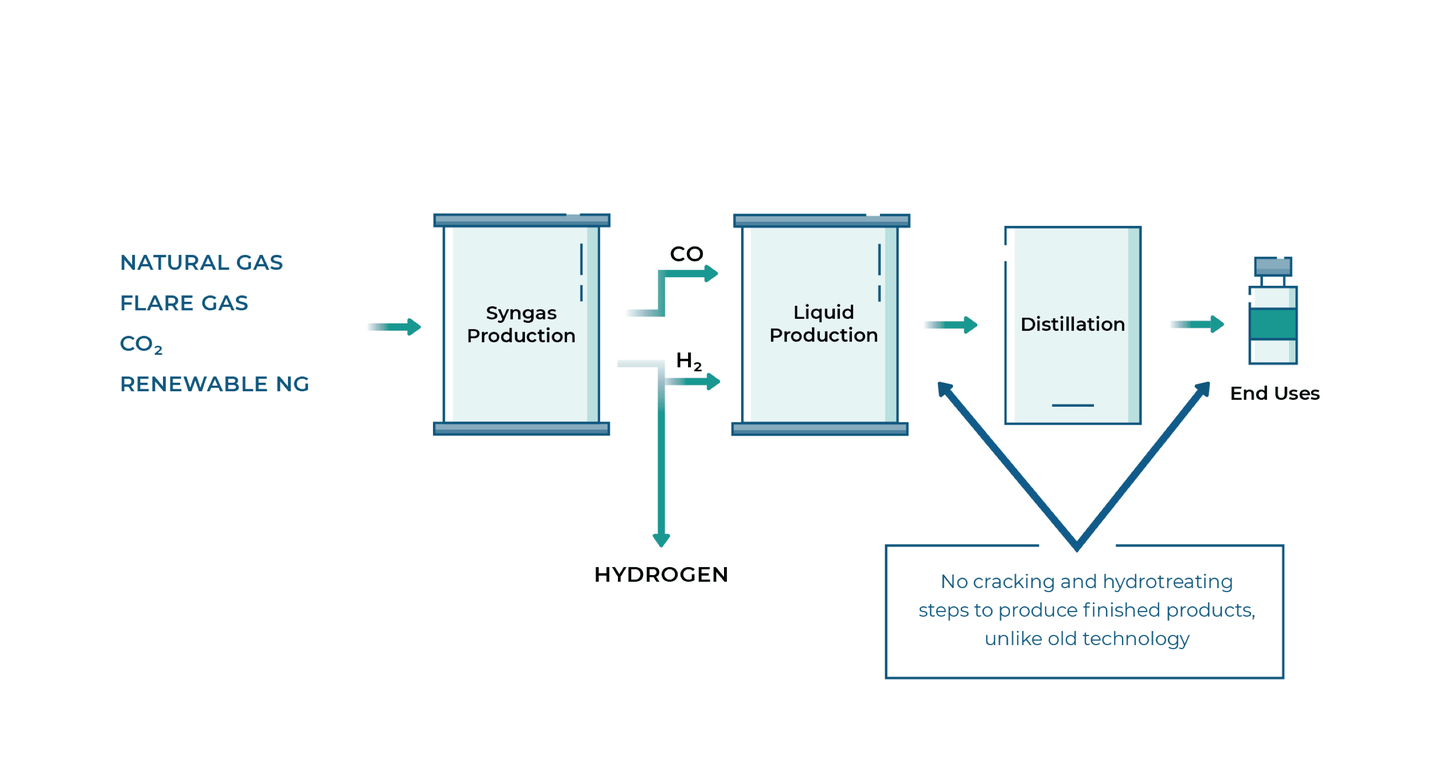

Process

ClearShift’s disruptive technology and process offers carbon reducing solutions without the headache of new product adaptation, leaving you to focus on your business while offering your customers a drop-in carbon friendly replacement.

We are scaling up our plants to 5,000 barrels per day based on our historical operations in West Texas and North Dakota. Our business leverages our proprietary GTL solution helping companies decrease their carbon footprint. With scale, we can meet growing global customer demand.

Renewable Natural Gas and CO2 Processing

ClearShift utilizes responsibly sourced Renewable Natural Gas and man-made CO2 for feedstock to manufacture our carbon neutral end products. Unlike new frontiers many are venturing, ClearShift plant's deploy commercially available technologies to not only our meet our carbon goals, but to mitigate the scaling risks newer companies experience. Our process and carbon accounting have been validated by multinational chemical corporations, recognizable lifecycle auditors, and global engineering companies.

The Clearshift cutting-edge process